Optimizing Distribution Center Efficiency with ErectaStep Conveyor Crossover Installation

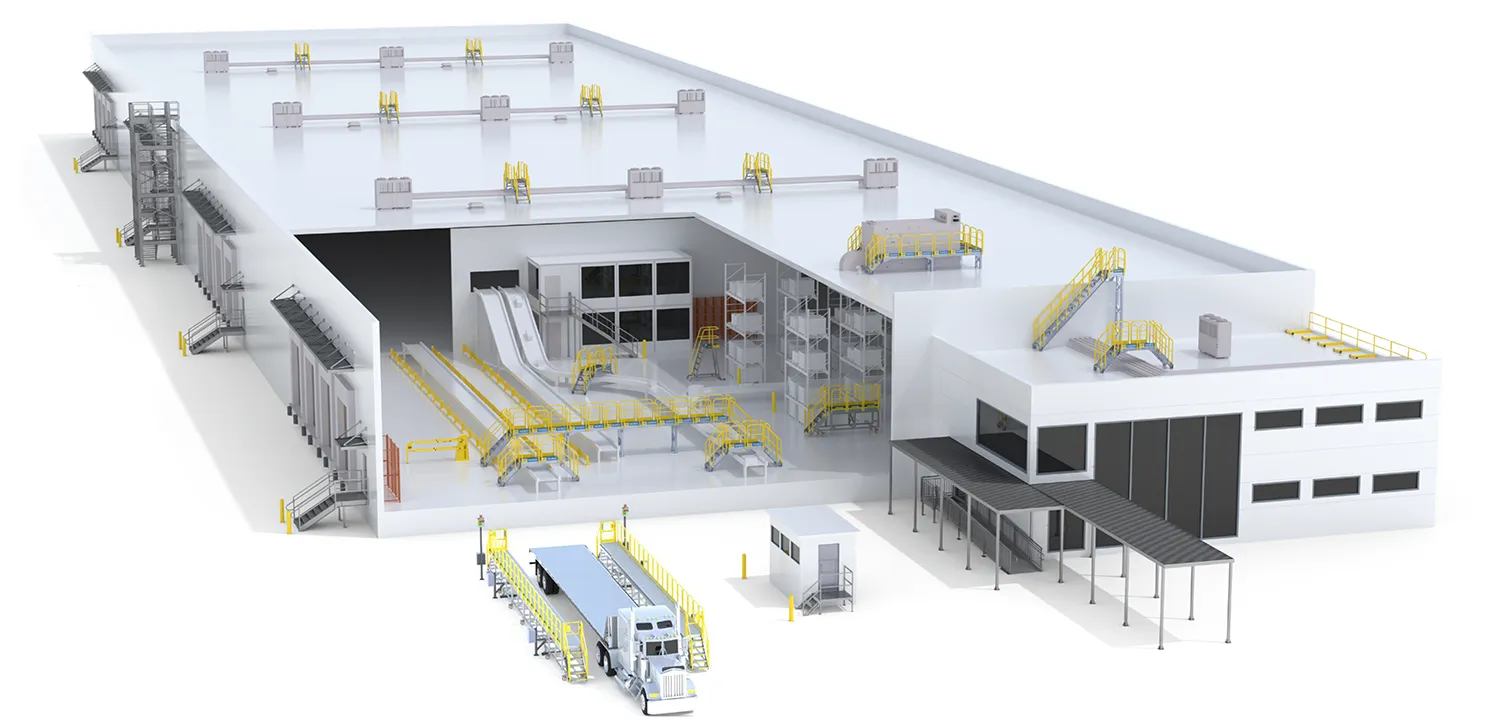

In the fast-paced environment of distribution centers like this facility in Colorado Springs, maximizing worker efficiency and safety is important for operational excellence and meeting productivity goals. ErectaStep’s modular conveyor crossover stair installation is designed to enhance navigation and streamline workflow, ensuring workers can move quickly and safely across the facility without circumventing conveyor systems.

Project Overview: Distribution Center, Colorado Springs

One of ErectaStep’s valued distributors installed a conveyor crossover stair system at this distribution center, utilizing in-stock parts and completing the project in just one day. This modular design allowed for easy assembly by a small crew without requiring special equipment or engineering services. The crossover provides nearly 9 feet of clearance, ensuring safe passage over the conveyor belt.

Benefits of ErectaStep’s Modular Design

- Efficient Installation: The modular construction of ErectaStep’s products allows for rapid installation, minimizing downtime and ensuring that operations continue uninterrupted.

- Safety and Compliance: The sturdy aluminum structure meets safety standards, providing secure access and reducing the risk of accidents.

- Cost-Effective: By using in-stock parts and not requiring specialized tools or engineering, the installation process is cost-efficient.

Enhancing Worker Efficiency in Distribution Centers

Distribution centers face numerous challenges in maintaining efficiency, including navigating large spaces and managing complex workflows. Here are some key strategies and statistics that highlight the importance of optimizing worker navigation and efficiency:

- Travel Time Reduction: Traveling can account for up to 50% of the picking time in warehouses, significantly impacting labor costs. ErectaStep’s conveyor crossovers help reduce travel time by providing direct access over conveyor systems, allowing workers to focus on core tasks.

- Optimized Warehouse Layout: Strategically designing warehouse layouts to minimize travel distances is crucial. Placing frequently picked items near shipping areas and creating efficient picking paths can significantly improve order fulfillment speed and reduce labor costs.

- Indoor Navigation and Positioning: Implementing indoor positioning systems can optimize routes for workers, reducing navigation time and improving overall efficiency.

- Labor Productivity Metrics: Tracking labor productivity metrics, such as orders processed per hour per employee, helps identify areas for improvement and ensures that staffing levels are adequate.

- Safety and Access Solutions: Providing safe and efficient access solutions like ErectaStep’s modular stairs and crossovers is essential for maintaining a high standard of safety and operational excellence.

Conclusion

ErectaStep’s conveyor crossover installation at this distribution center in Colorado Springs illustrates how prefabricated stairs can improve worker efficiency and safety in large distribution centers. By streamlining navigation and reducing travel time, these installations contribute to a more productive and cost-effective operational environment. As distribution centers continue to evolve, integrating efficient access solutions will remain a key strategy for optimizing performance and meeting customer demands.

Project Profile Summary:

- Location: Colorado Springs

- Product: ErectaStep Conveyor Crossover Stair

- Installation Time: Completed in one day

- Clearance: Nearly 9 feet

- Benefits: Enhanced worker safety, reduced travel time, efficient installation process

ErectaStep’s Contribution to Distribution Center Efficiency:

- Modular Design: Easy assembly and minimal downtime

- Safety Compliance: Meets OSHA standards for secure access

- Cost Efficiency: Uses in-stock parts, no special equipment required

By choosing ErectaStep’s modular access solutions, distribution centers can improve operational efficiency while ensuring a safe working environment for their employees.