Rooftop equipment requires ongoing maintenance and inspections, and compliance with OSHA regulations can be challenging.

Workers accessing roof-tops to maintain equipment are frequently met with accessibility challenges and obstacles such as pipes, skylights, ducts, and parapets, not to mention abundant trip and fall hazards. For roof-top accessibility and the ability to safely crossover over obstacles over 12″ height, an OSHA-compliant fixed roof-top stair or work platform is required.

When adding a crossover stair accessibility to roof-tops, a licensed Professional Engineer (P.E.) is required to ensure all conditions and contingencies are considered in the design. In addition to meeting the International Building Code (IBC), OSHA, and any additional local compliance requirements, an engineer will ensure that structural considerations such as weight distribution, ongoing wear (e.g., wind displacement), and long-term maintenance will need to be factored in. Cutting corners in an effort to get the job done should never be considered. Not only can this be costly and certified contractors and installers are always recommended. For example, a leak in a multi-story office building due to an improperly mounted stair unit and mechanical equipment will never be worth the perceived savings of getting the job done quickly by less capable installers.

Most commercial roofs are Built-Up Roof Membrane (BUR), made of rubber and/or tar. All roof-top stair installations should use non-penetrating mounting solutions to be effective. Roof curbs and equipment rails (see below for more info) are installed when the roof is created or redone. Both are raised structural elements located under the roof membrane. If your roof-top project requires these solutions it can be costly and time-consuming to add them. For lighter equipment, such as stairs, a less expensive base plate is all that is needed to be safe and effective.

Ideal for roof-top solutions

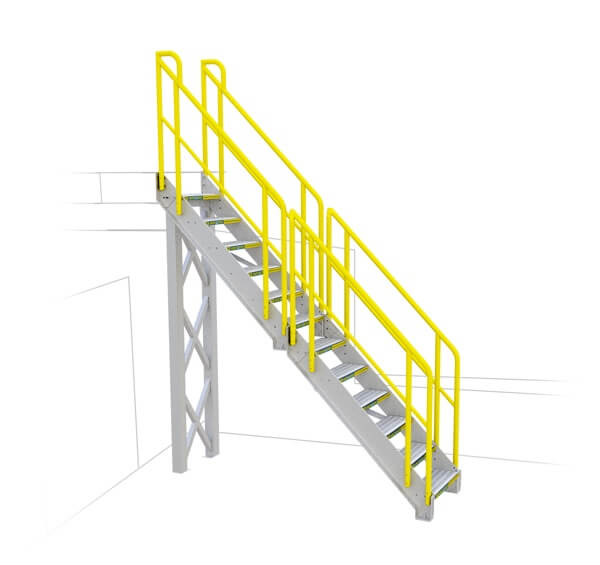

Because ErectaStep components are modular and made from lightweight, high-quality aluminum, no lift or crane is required for installation. All 5 ErectaStep components can be easily carried up by ladder saving time and money. While steel is known to rust and corrodes over time, especially in harsh weather conditions, aluminum is maintenance-free. Lighter construction also means less weight eliminating distribution complications common on roof-top installation.

Non-penetrating base plate installation

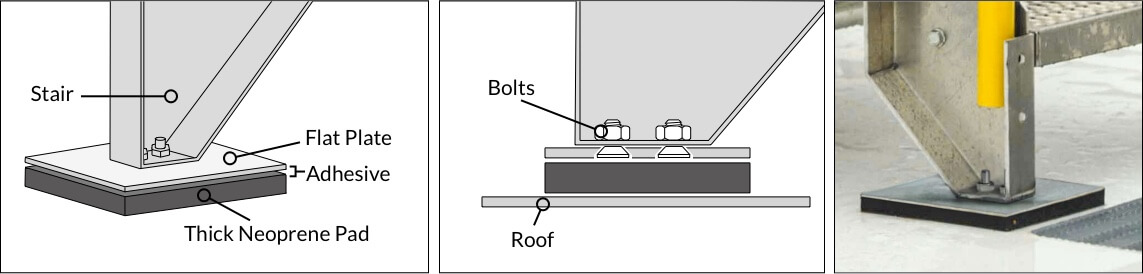

If a curb isn’t a possibility when mounting roof-top stairs, a metal base plate solution an easy and cost-effective alternative. In standard non-penetrating installations, the stair is anchored with countersunk bolts to a flat metal plate. The flat plate is rigid enough to distribute the weight over a wide surface area to prevent damage from point load and leaks. A thick neoprene pad is glued between the metal base plate and the roof, protecting the roof from the abrasive metal. Often times the neoprene pad floats on the roof surface. Local codes may require the stair unit to be anchored to the roof.

- Stair base plate on non-penetrating isolator pads helps mitigate leaks

- Flexible enough to be moved or adjusted. This includes leveling the roof-top stair.

- Weight distribution–distribute the load (point load) over a bigger area to prevent the stair weight from creating depressions that create pooling or ponding of water. It also protects the unit from penetrating the roof surface or creating structural damage.

- Weight distribution is especially important for styrofoam-insulated roofs.

- When a roof heats up, it can become soft and create depressions.

- Using neoprene pads or vibration isolator pads between the flat plate and roof surface prevents abrasion from movement or wind causing wear through the roof membrane.

- Base plates or mounts raise stairs out of standing water after rain/snow.

- Base plates are easier and less expensive to install.

Common reasons for rooftop stair, catwalk, or crossover installations

- To be OSHA compliant, obstacles such as pipes, ducts, or walls over 12” that must be crossed over by workers during ongoing maintenance, require a crossover stair.

- A permanent roof-top stair or ladder is required to access the roof or crossover a parapet or wall.

- Safe access to solar panels, roof-top units, and mechanical equipment

- Stair crossovers over skylights

- Safe access to work platforms for HVAC maintenance

- Filter changes and maintenance for air handlers and evaporator coils

- Roof-top access for the maintenance of power vents and roof centrifugal exhaust system

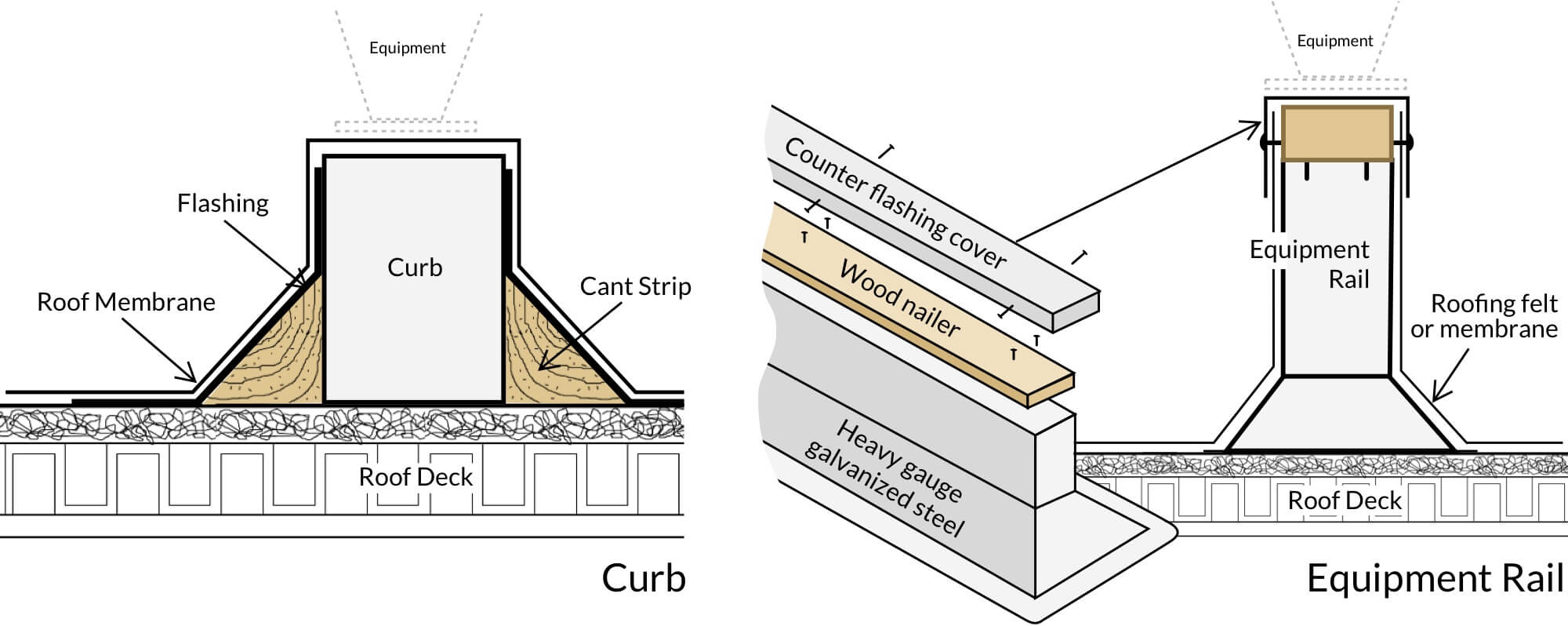

What is a curb or equipment rail?

A roof-top curb is used to mount mechanical units (such as air conditioning or exhaust fans), stairs, stair crossover or skylights on a roof. A curb used on commercial roofs is typically a raised structural element made from wood or concrete located under the roof membrane. Flashing and a cant strip are used in the transition from the roof to the curb. Flashing is usually a thin piece of galvanized steel used where the roof plane meets a vertical surface, the curb in this instance. A cant strip is used to create a smooth transition from the roof deck to the curb.

Because the curb is raised under the roof membrane, stairs and mechanical equipment can be anchored directly to the curb. Similar to curbs, equipment rails are a long structural galvanized steel unit designed to mount roof-top equipment, pipe roller supports, and duct pedestals, which also do not penetrate the roof and are anchored using treated wood.

Common Rooftop Stair Configurations

ErectaStep’s modular metal stairs are OSHA compliant and made up of 5-components that can be configured for any installation with no custom engineering or fabrication required. Common ErectaStep roof-top configurations include crossover stairs, roof-top access stairs, catwalks, roof-top crossover stairs, HVAC access platforms, and metal stairs to multi-level roofs or mezzanines.

See all common metal stair configurations.

Rooftop Stair Compliance

In addition to OSHA and IBC compliances, occasionally, additional codes must be followed to meet local industry compliance standards. In these cases, an engineer experienced with roof-top installations must be consulted. Aside from worker safety and building codes, wind events and seismic activity often need to be factored in when designing safe and effective solutions as well.

OSHA

Workers maintaining roof-top equipment at heights of 6 feet or more require access to stair platforms or conventional fall protection such as guardrail systems, safety net systems, or personal fall arrest systems. §1926.501(b)(1)

OSHA requires a crossover stair for obstacles over 12″

IMC-2003 306.5 Equipment and appliances on roofs or elevated structures.

Summary of IBC codes for stairs

- A permanent stair access solution is required for equipment and appliances installed on a roof that exceeds 16’ in height.

- Roof obstacles and obstructions over 30″ high require a permanent method of access, such as a crossover stair.

- A roof with a slope of 33% slope or greater requires a permanent stair solution.

- Permanent ladders and stairs install to or on a roof shall comply with the following minimum design criteria:

- Side railing shall extend above the parapet or roof edge at least 30”.

- The space between the ladder rung should not exceed 18”.

- Ladders must have at least 6” of toe space.

- 18” minimum spacing between rails

- Ladder rungs must be no less than 0.75” in diameter and capable of withstanding a load of 300 lbs.

- Ladders over 30’ in height need a landing rated to withstand 100 lbs. per sq. ft.

- Ladders must be corrosion resistant.

- Roof-top catwalks need to be as least 24” wide and require railings.

Considerations for severe winds and seismic activity

Roof-top stairs and equipment must be engineered and mounted to withstand forces of nature such as high winds and seismic activity. Anchoring is required to secure the curb to the roof and the roof-top air handling equipment or stairs to the curb. To meet certain local code compliances, a spring isolation system may be required. An engineer will need to evaluate your particular application and recommend the appropriate solution that meets the requirements of your project’s applicable building codes. Compliance verification and calculations can be provided and are performed by a licensed professional engineer for the seismic zone in which they are to be installed.